bostaurus

Well-Known Member

Not sure if this is the forum for this question but here goes-

I had a question about flashing or incasing a clear bottle in another color. I searched the Historic Glass website but did not find anything. I sure it was not a common practice on ordinary bottles. I understand that it was a cheaper way of making a colored bottle without the expense of coloring a larger batch of glass.

They gather up clear glass then dip that in the colored glass before blowing the bottle.

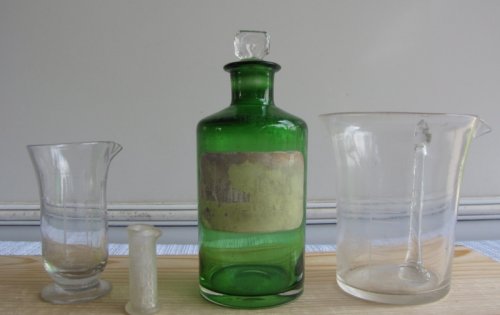

I have a couple in my collection. One is a fairly modern Pyrex apothecary that is flashed with red. The other is late 1880's , ground pontil, and is flashed with emerald green.

That is the one I have problems with. This one seems to have the colored glass on the inside. If you look close some of the color is missing on the neck where the glass was ground for the stopper. If you look at the bottle at eye level, as it sits on the shelf, you can see that the entire, thick base of the bottle is clear except on the bottom inside. It is a strange bottle as it looks like an bright emerald green until you get to the bottom. It is the only one I have had that has the color on the inside.

I would just like to know if any one has any information on flashing of bottles. I think I have heard it called casing too. I know it was used alot in cameo glass but that started out with expensive glass all around.

I had a question about flashing or incasing a clear bottle in another color. I searched the Historic Glass website but did not find anything. I sure it was not a common practice on ordinary bottles. I understand that it was a cheaper way of making a colored bottle without the expense of coloring a larger batch of glass.

They gather up clear glass then dip that in the colored glass before blowing the bottle.

I have a couple in my collection. One is a fairly modern Pyrex apothecary that is flashed with red. The other is late 1880's , ground pontil, and is flashed with emerald green.

That is the one I have problems with. This one seems to have the colored glass on the inside. If you look close some of the color is missing on the neck where the glass was ground for the stopper. If you look at the bottle at eye level, as it sits on the shelf, you can see that the entire, thick base of the bottle is clear except on the bottom inside. It is a strange bottle as it looks like an bright emerald green until you get to the bottom. It is the only one I have had that has the color on the inside.

I would just like to know if any one has any information on flashing of bottles. I think I have heard it called casing too. I know it was used alot in cameo glass but that started out with expensive glass all around.