cmulliganNWI

Well-Known Member

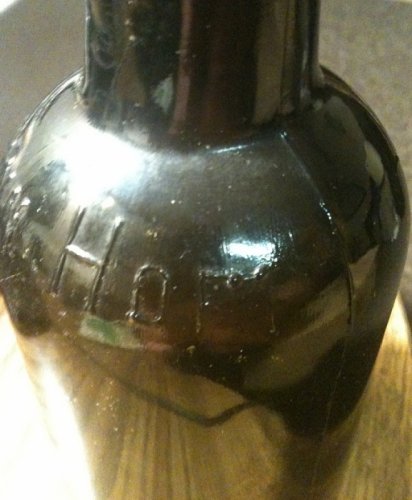

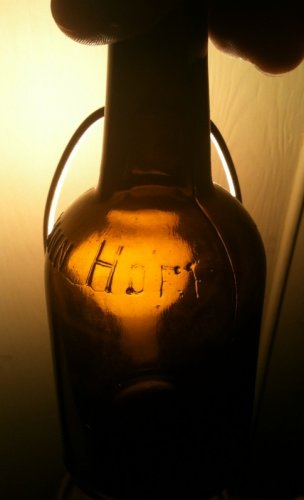

I picked up this Johann Hoff a while back. The embossing seems peculiar to me. I haven't seen a ton of these but I know they are fairly common. The ones that I have seen have a much bolder embossing while the embossing on this bottle is fainter and has the appearance of being done by hand. Almost looks like a soldering iron does on metal. Anyone ever seen a Hoff with this embossing or embossing like this done by other bottlers? Anyone have a guess on a year for this one?

Thanks!

Chris

Thanks!

Chris