willong

Well-Known Member

Here you go Jstorm: https://www.antique-bottles.net/threads/is-there-a-better-way-to-cut-copper-wire.695109/#post-750508Yes I thought of that when RobbyBobby made his comment. I have been working with BBs and copper pieces. A lot of cutting! Lol

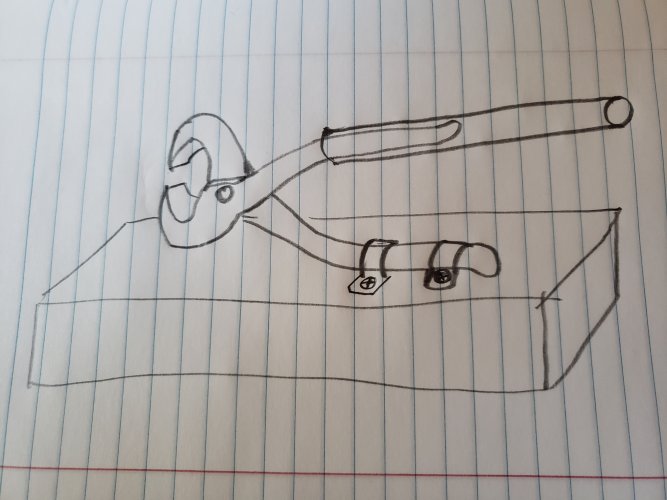

Forum member embe did the search and found the copper wire cutting discussion that I vaguely remembered. It is actually a quite simple setup if you have a power drill or, better yet, a drill press. I did not remember that the cutter was simply a drill bit. Since that is the case, the lengths of the cut pieces of copper wire are determined by the flute depth of the drill bit used. Flute depth is primarily a function of a bit's diameter, but does vary somewhat among types of bits and manufacturers. Consequently, you have a lot of control over the size of the finished pieces simply by selecting a bit that will produce the desired length.

It is still "a lot of cutting" but will speed up the process considerably and likely prevent you developing a case of carpal tunnel syndrome.