You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Digging at the Whitall Tatum factory?

- Thread starter RIBottleguy

- Start date

baltbottles

Well-Known Member

Philadelphia museum of art

ORIGINAL: KentOhio

I read a glassblower's diary once. It was from the late 1860s. Unfortunately it contained no glass secrets. All it had was when he woke up each day, how the weather was, and I think he went to a dance one Saturday night and played baseball another day.

I have some molds and have experimented with them a little. I've used aluminum and iron. The aluminum mold I used three times to make a bottle with a rest of about 20 minutes in-between each bottle. Each turned out better than the last, each time with less whittle and more definition to the design. The iron mold I used three times to press an object, with about 5 minutes of rest in-between each piece. The first was whittled and didn't fill completely, the second was pretty good, and the third looked the best but nearly stuck to the mold. I have the impression in my mind that molds need to be the right temperature between too chilled with no detail, and too hot where the glass sticks. Iron pontils, after all, are iron too, that's stuck to the glass.

I read somewhere that Fenton's snap cases were brushed with lime to prevent sticking.

I also saw a patent from the 1880s or so where someone had the idea to have a core of graphite-rich iron as the interior of a cast iron mold.

Molds of the 1850s seem to have been thin like the Coventry mold but iron like later molds. The Philadelphia museum of art has some on its website, if you search. They have a Jenny Lind mold, barrel bitters, booze, and some others I remember.

Those molds are amazing.

It sounds like from your glass blowing experience the mold needs to be at the proper temperature for bottles to be correct. Can we see some pictures of your molds and of the pieces you have blown.

Chris

RED Matthews

Well-Known Member

Hi epackage - I don't know what happened It just didn't cut and paste properly. I went on to explain about a couple other foundries and all I can say is that sometimes when I cut and paste from Microsoft Word to the control V for these forum notes - it does strange things.

Sorry RED Matthews

Sorry RED Matthews

RED Matthews

Well-Known Member

Hi, I didn't find the original draft. Here is another list I did find.

Mold Equipment Metals.doc

BinneyDV metal: 15% Ni, 12% Al, 6% Zn. & Balance Cu.

Binney Foundry 51C metal: A mold iron that had 1/8th bronze in the melt.

And had a secret annealing process used.

Kelley Foundry # 4 Mold Iron

Nodular Iron

Overmyer Mold Company Mold Iron

Bronze

Coast Metals 50 B castings and powder.

Dameron Alloy Foundries HR metal Rc 30 40 50 w/ some age hardening alloy ??

Wall Colmony Company Cast nickel alloys and powder fed metals.

For several years I sold special cast alloys to the worlds glass industry for DAMERON Alloy Foundries.

RED Matthews

Mold Equipment Metals.doc

BinneyDV metal: 15% Ni, 12% Al, 6% Zn. & Balance Cu.

Binney Foundry 51C metal: A mold iron that had 1/8th bronze in the melt.

And had a secret annealing process used.

Kelley Foundry # 4 Mold Iron

Nodular Iron

Overmyer Mold Company Mold Iron

Bronze

Coast Metals 50 B castings and powder.

Dameron Alloy Foundries HR metal Rc 30 40 50 w/ some age hardening alloy ??

Wall Colmony Company Cast nickel alloys and powder fed metals.

For several years I sold special cast alloys to the worlds glass industry for DAMERON Alloy Foundries.

RED Matthews

tigue710

Well-Known Member

(in reply to kungfufighter)

[Send Private Message]

ORIGINAL: KentOhio

I read a glassblower's diary once. It was from the late 1860s. Unfortunately it contained no glass secrets. All it had was when he woke up each day, how the weather was, and I think he went to a dance one Saturday night and played baseball another day.

I have some molds and have experimented with them a little. I've used aluminum and iron. The aluminum mold I used three times to make a bottle with a rest of about 20 minutes in-between each bottle. Each turned out better than the last, each time with less whittle and more definition to the design. The iron mold I used three times to press an object, with about 5 minutes of rest in-between each piece. The first was whittled and didn't fill completely, the second was pretty good, and the third looked the best but nearly stuck to the mold. I have the impression in my mind that molds need to be the right temperature between too chilled with no detail, and too hot where the glass sticks. Iron pontils, after all, are iron too, that's stuck to the glass.

I read somewhere that Fenton's snap cases were brushed with lime to prevent sticking.

I also saw a patent from the 1880s or so where someone had the idea to have a core of graphite-rich iron as the interior of a cast iron mold.

Molds of the 1850s seem to have been thin like the Coventry mold but iron like later molds. The Philadelphia museum of art has some on its website, if you search. They have a Jenny Lind mold, barrel bitters, booze, and some others I remember.

A lot of answers there, thanks for bringing it up! Here is a link to the barrel bitters mold, which is known as a treadle mold, and was operated by a single person with the use of a pedal to open and close the mold...

http://www.philamuseum.org/collections/permanent/50524.html

surfaceone

Well-Known Member

- Joined

- Dec 9, 2008

- Messages

- 11,161

- Reaction score

- 23

- Points

- 0

ORIGINAL: KentOhio

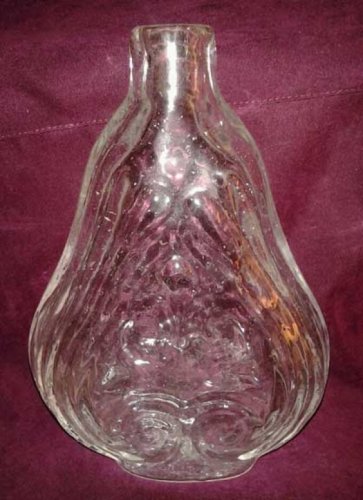

Here's the base. It's still a pretty badly made bottle, haha, but neat nonetheless.

Bravo Brian!

I trust you got an "A" in Foundry, and a definite "A+" in bottle blowing. Well done, sir. Thanks for showing us.

AntiqueMeds

Well-Known Member

Here's the third bottle made, the one with the best impression.

in the year 2099 collectors will see that bottle for sale on GooglBay for 10,000 Chinese plastic dollars and argue about its origins...

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 6

- Views

- 1K

Latest posts

-

-

-

I have an old soda bottle with a rounded bottom

- Latest: Abn@9352920

-

-

Rare Utah can added to my collection!

- Latest: CanadianBottles

Latest threads

-

-

I have an old soda bottle with a rounded bottom

- Started by Abn@9352920

- Replies: 0

-

-

-

Interesting bottle and contents find at George Washington's Mount Vernon Estate!

- Started by willong

- Replies: 0

-

Once in a lifetime? Moral of the story never overlook fallen tree stumps

- Started by Bluestreak39

- Replies: 2