Picked up this bottle in a box lot and am curious about the mold lines...There is a horizontal line below the shoulder, and then two vertical mold lines from there to the applied top...obviously a three part mold, but no mold lines from the shoulder down...just need someone to explain this bottle to me...I'll try to attach the pic's...Thanks in advance..!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Picked this bottle in a box lot...Have ?'s..

- Thread starter nammlif

- Start date

botlguy

Well-Known Member

- Joined

- Nov 20, 2009

- Messages

- 5,414

- Reaction score

- 12

- Points

- 0

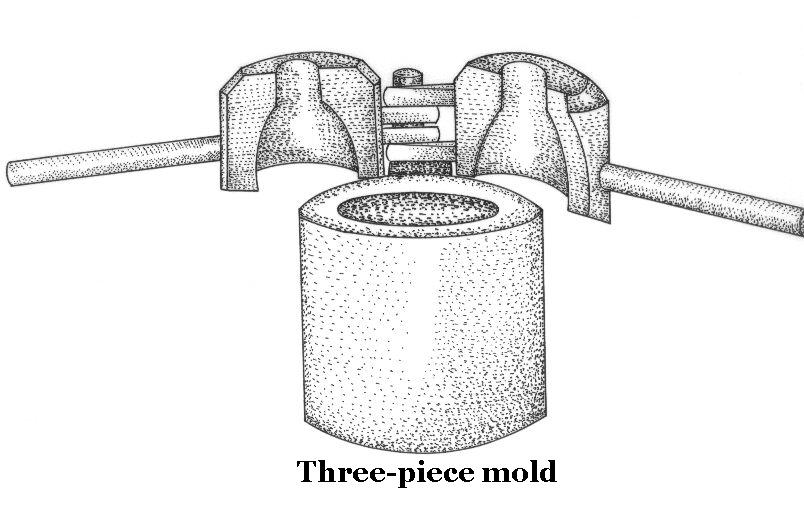

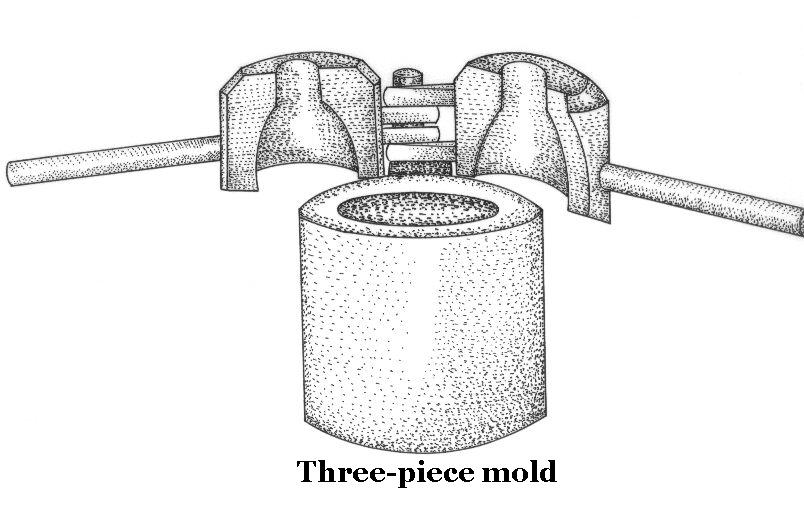

I am not certain my terms will coincide with others but the bottle was blown in some form of one piece mold similar to or including a hole in the ground with a two piece mold from shoulder up. When ready, the upper mold was opened and the completed bottle was lifted out and the blow pipe removed from the neck and completed by applying or tooling the collar. That's the simplified version but pretty accurate I believe. Jim

botlguy

Well-Known Member

- Joined

- Nov 20, 2009

- Messages

- 5,414

- Reaction score

- 12

- Points

- 0

1880s to perhaps as late as 1910 or so. If British it could be even a little later. I doubt it's as early as 1870s. Jim

cowseatmaize

Well-Known Member

From. http://www.sha.org/bottle/body.htm#Mold Seams

The text starts a little more than half way down.

The text starts a little more than half way down.

botlguy

Well-Known Member

- Joined

- Nov 20, 2009

- Messages

- 5,414

- Reaction score

- 12

- Points

- 0

Nice going Eric. a picture is worth a thousand words except to a blind person. [ ] Jim

] Jim

RED Matthews

Well-Known Member

I need to point out here that the dip mold part of these set=ups are made as a casting that can have the cast cavity chilled by a solid core of iron - which when done - creates a glass contact area that has dendritic iron metal in the glass contact area. Dendritic iron has a slower heat transfer speed whch lets the glass blow with even wall thickness. So it isn't whittle - but us cold mold-ripple of thickness structure. RED Matthews

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 6

- Views

- 3K

- Replies

- 2

- Views

- 948

Latest threads

-

-

-

-

-

-

Bayer Aspirin bottle or something else?

- Started by Mlzeigler

- Replies: 1