sandchip

Well-Known Member

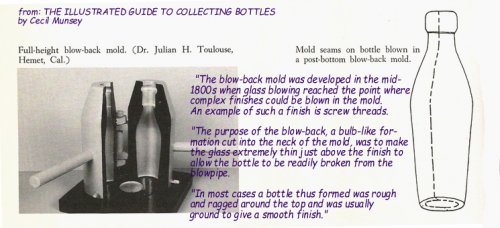

Your bottle does indeed have an applied lip. I have plenty of turn-molded bottles with applied lips. What we call tooled top bottles were formed in full height blowback molds where the bottle and lip are all formed in the mold which enlarges above the top, resulting in the glass becoming very thin at that area, so the blowpipe and the thin glass is knocked off instead of being wetted off. Then the lipping tool is inserted and the bottle finished, saving time over the course of a workday and producing more bottles. I did see an early video (around 1900) of workers blowing little drugstore bottles like this. They were flat out gettin' it! Anyway, the fact that the glass becomes so thin in the bulbous blowback portion of the mold above the lip would preclude any turning of the bottle in the mold. So, just because turn-molded bottles were popular in the latter part of the 1800s when tooled tops became so prevalent, doesn't mean that all earlier manufacturing techniques were abandoned. In the case of turn molding, the gaffers couldn't. I have more applied top turn-molded bottles than tooled top examples. It's conceivable that, in the case of tooled top, turn-molded examples, that a full height mold was used, the bottle wetted from the blowpipe just at the top of the lip, and the top tooled. I have a whiskey like this. I'm not sure if this is the case or not. Still stewing on that one.

As far as inserting the finger into the mouth of the bottle to check for an applied top, sometimes that works, sometimes it does not. It all depends on the size of rod portion of the lipping tool, temperature of the glass, etc.

Hope this helps, if it all makes any sense.

Another thing: we can't always pigeonhole things into defined time periods as far as technology goes. How long have smart phones been on the market? And many folks still use flip phones, and a few, rotary desk phones? There will always be periods of transition of varying lengths in regards to the acceptance and use of all types of technologies.

As far as inserting the finger into the mouth of the bottle to check for an applied top, sometimes that works, sometimes it does not. It all depends on the size of rod portion of the lipping tool, temperature of the glass, etc.

Hope this helps, if it all makes any sense.

Another thing: we can't always pigeonhole things into defined time periods as far as technology goes. How long have smart phones been on the market? And many folks still use flip phones, and a few, rotary desk phones? There will always be periods of transition of varying lengths in regards to the acceptance and use of all types of technologies.