SODAPOPBOB

Well-Known Member

- Joined

- Mar 10, 2010

- Messages

- 11,502

- Reaction score

- 49

- Points

- 0

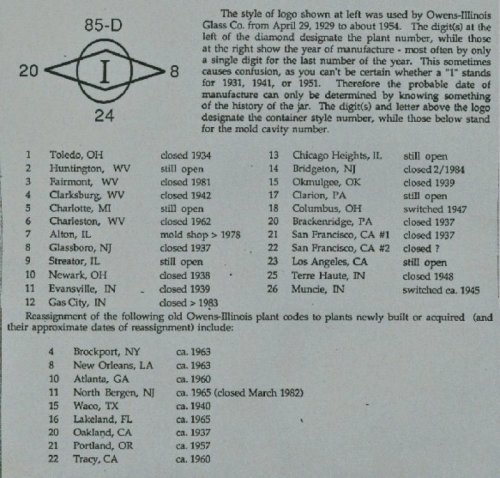

Roger ~

I have seen references to the term "cavity" numerous times but am totally confused about it, which you might be able to educate me on. As we know, the word "cavity" is defined as a blank or empty space. So why would a mold shop need two seperate numbers, one for the mold itself and one for the mold's "empty space?" For me it just doesn't make sense. I once read, but have since lost track of the link, that stated the bottom number ... (with the example below being a 3 - which I inserted the dots to center it)

20 <(I)> 48

.......3........

... was a "production indicator," meaning that certain molds were prone to greater use, and that the higher the number the higher the typical production count. In other words, a number 3 might indicate a typical production run of 3,000 bottles for a particular mold, whereas a number 6 indicates a typical production run of 6,000 bottles. Have you ever heard of this before? And is it possibly true?

Thanks.

Bob

I have seen references to the term "cavity" numerous times but am totally confused about it, which you might be able to educate me on. As we know, the word "cavity" is defined as a blank or empty space. So why would a mold shop need two seperate numbers, one for the mold itself and one for the mold's "empty space?" For me it just doesn't make sense. I once read, but have since lost track of the link, that stated the bottom number ... (with the example below being a 3 - which I inserted the dots to center it)

20 <(I)> 48

.......3........

... was a "production indicator," meaning that certain molds were prone to greater use, and that the higher the number the higher the typical production count. In other words, a number 3 might indicate a typical production run of 3,000 bottles for a particular mold, whereas a number 6 indicates a typical production run of 6,000 bottles. Have you ever heard of this before? And is it possibly true?

Thanks.

Bob