You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

bottom marks on strapped sided flasks

- Thread starter privvydigger

- Start date

privvydigger

Well-Known Member

privvydigger

Well-Known Member

privvydigger

Well-Known Member

nobody? ever saw these before.....i'm stumped

NorCalBottleHunter

Well-Known Member

I myself have not seen the base marks on the last two, nor the first but the anchor seems to pop up on a lot of flasks, I have just not seen it there before. very interesting! I have collected quite a lot of unembossed flasks and not one that I have has the same base markings of those, I am eager to hear more feedback on this post, good stuff, P.D!

cobaltbot

Well-Known Member

Have not seen the last two either, but have seen anchors on both amber and aqua flasks. Even David Whitten says unknown on them. Rumors about Baltimore glassworks exist but only rumors, no proof. They are found in the area though.

privvydigger

Well-Known Member

would you say the anchor is a hige mold and older?

The dotted ones top is really crude as is the O

The dotted ones top is really crude as is the O

RED Matthews

Well-Known Member

Hello privvydigger and others. This is an interesting thread of a subject that I have been studying and collecting data on for some time now. Thanks for getting it started. At least it tells me that others are interested in the marks on old bottles. These marks can tell us the story of their creation most of the time. If they don’t they remain bottlemysteries.

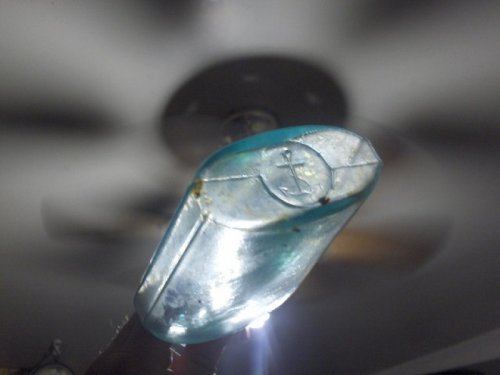

The first bottle you pictured in this thread regarding some of your strap side flasks, is a Round Key Lock Bottom Post. The parting line is diagonal and obviously the front half of the bottom hinged mold opened the half round of the post on the ridged parting line near the bottom of the anchor. This bottle with the anchor would be like one Mark guntherhess wrote a post on a few days ago where there were embossed letters on the bottom of a rectangular medical bottle. I just recently acquired a two part BIM med bottle that had a Rectangular Key Lock on the bottom parting line. It is the first one that I have seen and the rectangular key is about ½†x 1†wide and the sides seem to have a slight taper on them to help center the lock up of the two mold halves. This system wasn’t used much as far as I know, and I am sure it would be a nightmare to keep it clean for good tight lock-ups.

The second bottle you pictured illustrates four vent holes. These were obviously drilled and doweled in the plate type bottom for the mold that had the cavity recessed in the plate and one of the mold halves would have been fastened to the plate, and the other side hinged half of the mold would have closed to the fastened one with no doubt two dowel pins and matching holes in the other mold half, for positive locating for the final blow of the parison. Early mold venting is a study that I am preparing a blog to cover. The problem goes back to the start of BIM bottle making and has been accomplished in many ways through the years. The problem being letting the trapped air between the inserted parison and the cavity of the mold, get out of there so the glass could be blown out to the mold cavity walls in the final blow.

Now then, for the third pictured bottle, this is a “bottlemystery†as you said. The strap side picture shows the existence of diagonal parting on the lower corner of the right hand side rib and the top corner of the upper strap side rib. Those two glass corners protrude enough to let me recognize that. I am confident that the rings were made by vent pins placed in the machined bottom cavity cut out in the mold base plate. The question is do they have a common center? They look like they are slightly askew center-wise. If the centers are not the same it may require a different study.

Early Mold Venting Studies have been in my study efforts for a long time. I have collected a lot of notes, bottles and pictures of bottles that show some unique evidence of venting methods used. The round circle vents were used a lot in the Civil War era of bottle making and a lot of early beer and ale bottles have these large circular vents. The dowel that was inserted had thin flats machined vertically around them to let the air pass down and out of the mold. They had to be a bugger to keep clean and I am sure that in Mold Repair they had to be pushed out, cleaned and pushed back into the location. One needs to realize that the use of cast iron molds requires the use of a swabbing oil in the mold cavities. This oil was a culprit for clogging a lot of the air venting passages. This is also a good time to mention that the bottle blowers also used dry powdered sulfur, and white rubber sneaker soles or a paint stick to lubricate problem points in molds. These things burned and clogged venting concepts also.

Well like always when I write, I create TMI. And I am sure you all realize that in all of these cases, one almost has to get their hands on the bottle to catch all of the functions incorporated in the early molds.

The first bottle you pictured in this thread regarding some of your strap side flasks, is a Round Key Lock Bottom Post. The parting line is diagonal and obviously the front half of the bottom hinged mold opened the half round of the post on the ridged parting line near the bottom of the anchor. This bottle with the anchor would be like one Mark guntherhess wrote a post on a few days ago where there were embossed letters on the bottom of a rectangular medical bottle. I just recently acquired a two part BIM med bottle that had a Rectangular Key Lock on the bottom parting line. It is the first one that I have seen and the rectangular key is about ½†x 1†wide and the sides seem to have a slight taper on them to help center the lock up of the two mold halves. This system wasn’t used much as far as I know, and I am sure it would be a nightmare to keep it clean for good tight lock-ups.

The second bottle you pictured illustrates four vent holes. These were obviously drilled and doweled in the plate type bottom for the mold that had the cavity recessed in the plate and one of the mold halves would have been fastened to the plate, and the other side hinged half of the mold would have closed to the fastened one with no doubt two dowel pins and matching holes in the other mold half, for positive locating for the final blow of the parison. Early mold venting is a study that I am preparing a blog to cover. The problem goes back to the start of BIM bottle making and has been accomplished in many ways through the years. The problem being letting the trapped air between the inserted parison and the cavity of the mold, get out of there so the glass could be blown out to the mold cavity walls in the final blow.

Now then, for the third pictured bottle, this is a “bottlemystery†as you said. The strap side picture shows the existence of diagonal parting on the lower corner of the right hand side rib and the top corner of the upper strap side rib. Those two glass corners protrude enough to let me recognize that. I am confident that the rings were made by vent pins placed in the machined bottom cavity cut out in the mold base plate. The question is do they have a common center? They look like they are slightly askew center-wise. If the centers are not the same it may require a different study.

Early Mold Venting Studies have been in my study efforts for a long time. I have collected a lot of notes, bottles and pictures of bottles that show some unique evidence of venting methods used. The round circle vents were used a lot in the Civil War era of bottle making and a lot of early beer and ale bottles have these large circular vents. The dowel that was inserted had thin flats machined vertically around them to let the air pass down and out of the mold. They had to be a bugger to keep clean and I am sure that in Mold Repair they had to be pushed out, cleaned and pushed back into the location. One needs to realize that the use of cast iron molds requires the use of a swabbing oil in the mold cavities. This oil was a culprit for clogging a lot of the air venting passages. This is also a good time to mention that the bottle blowers also used dry powdered sulfur, and white rubber sneaker soles or a paint stick to lubricate problem points in molds. These things burned and clogged venting concepts also.

Well like always when I write, I create TMI. And I am sure you all realize that in all of these cases, one almost has to get their hands on the bottle to catch all of the functions incorporated in the early molds.

privvydigger

Well-Known Member

that their paragraph capped of a hell of a diggin year. I love learning new things about bottles......well 3 hours to go anyway

NorCalBottleHunter

Well-Known Member

I agree! I really love and enjoy this forum, great people, and great info! I wish the best to all this new year!

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 2

- Views

- 945

- Replies

- 4

- Views

- 2K

- Replies

- 4

- Views

- 1K

Latest threads

-

Who made this case gin?

- Started by Boundary Country

- Replies: 1

-

-

Killer Dig with Pot Lids and lot of other stoneware!

- Started by RIBottleguy

- Replies: 0

-

-

-