baltbottles

Well-Known Member

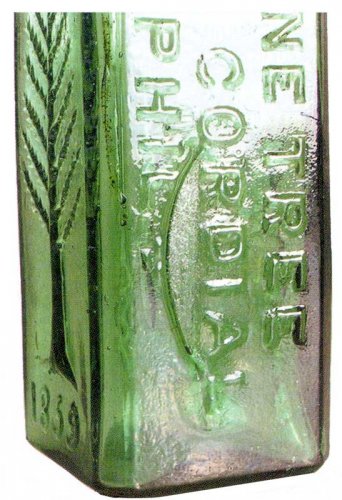

Kentohio you are exactly right on how this type of defect is formed in the glass. If you ever get the chance to see one in cross section on a broken bottle its clearly two separate layers of glass. And it was not applied over a hole in the bottle either.

As you stated while trying to close the mold the gather got partly caught between the two mold halves and was cooled into a pressed fin shape. This would not have allowed the mold to close properly then the mold would be reopened and the gather turned in the mold pushing this fin flat against the side of the gather then the gather would be blown to create the finished bottle. This fin of glass haveing been too cool to take on the shape of the mold very well. This is why these don't usually have embossing on them. This also explains why these types of defects tend to be vertical in nature running parallel to the mold seams of the bottle. However they do not have to be near the seam its self due to the turning of the gather in the mold before blowing. This lapse in time between the turning and the blowing could also explain why some of these are not always perfectly vertical but may skew slightly to the diagonal

Furthermore if this was a repair to the mold itself then there would be many of the same bottle with a matching defect. I have never seen two of the same bottle with this defect that are identical in size shape and placement.

Chris

As you stated while trying to close the mold the gather got partly caught between the two mold halves and was cooled into a pressed fin shape. This would not have allowed the mold to close properly then the mold would be reopened and the gather turned in the mold pushing this fin flat against the side of the gather then the gather would be blown to create the finished bottle. This fin of glass haveing been too cool to take on the shape of the mold very well. This is why these don't usually have embossing on them. This also explains why these types of defects tend to be vertical in nature running parallel to the mold seams of the bottle. However they do not have to be near the seam its self due to the turning of the gather in the mold before blowing. This lapse in time between the turning and the blowing could also explain why some of these are not always perfectly vertical but may skew slightly to the diagonal

Furthermore if this was a repair to the mold itself then there would be many of the same bottle with a matching defect. I have never seen two of the same bottle with this defect that are identical in size shape and placement.

Chris