GuntherHess

Well-Known Member

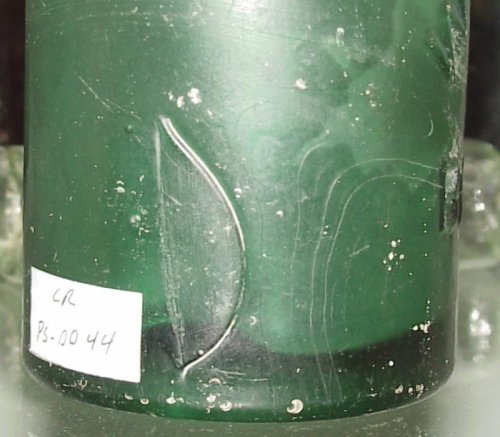

I find it difficult to accept it is a mold repair.

There weren't a huge number of molds made for early bottles. If it was a repair I would expect two matching examples wouldnt be too hard to find.

Just taking Townsends sarsaparillas as an example, the mold modifications there are fairly well known and multiple examples show up.

There weren't a huge number of molds made for early bottles. If it was a repair I would expect two matching examples wouldnt be too hard to find.

Just taking Townsends sarsaparillas as an example, the mold modifications there are fairly well known and multiple examples show up.